Packaging serves not only as a protective covering for the goods it contains, but also as an important part of the way businesses represent their company through branding, control of logistics, and developments toward sustainable practices. As companies see an increase in environmental awareness among consumers and face rising costs on materials due to manufacturing processes and resource availability, the adoption of Papierbox-Verpackung will only continue to grow as it has been adopted broadly by various types of companies.

Now that we have established the reasons for the increasing number of companies adopting paper boxes for their packaging, we can answer the question: What is driving this increased adoption?

Below, we will systematically analyze why paper box packaging possesses extremely high comprehensive value from a professional, pragmatic perspective, geared towards corporate procurement and brand owners.

Paper Boxes: A High-Value Packaging System

Unlike materials such as plastics, metals, or acrylic, which offer only single advantages in specific areas, paper boxes form a more balanced value structure in terms of functionality, sustainability, cost efficiency, and brand presentation.

Lightweight and Structural Strength Combined

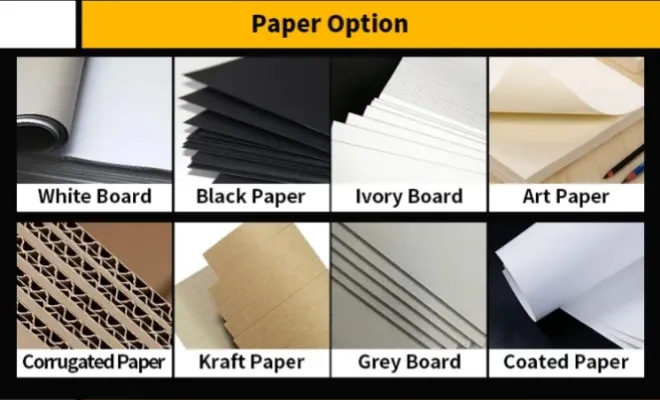

Modern paper materials, after industrial processing, can provide reliable structural performance while maintaining lightweight properties. Commonly used materials include:

- Kraft paper: Pressure-resistant, environmentally friendly

- White cardboard: Suitable for retail packaging

- Greyboard: Used for high-end gift boxes

- Corrugated board: E-commerce, logistics, and transportation packaging

- Specialty paper: Used to enhance brand value

With proper structural design, excellent pressure resistance, cushioning, and transport stability can be achieved.

Can Paper Boxes Really Protect Products? The Key Lies in Design and Engineering

Many brands wonder: Are paper boxes sufficient to protect their products?

The answer depends on three factors: materials, structure, and testing.

A paper box itself does not equal protection, but professional design combined with the right materials can achieve high reliability.

Four Core Factors Determining Protective Performance

① Material Type and Thickness

- Grey Board: 1.5–3mm for gift boxes

- Corrugated: E/B/F flute structure for transportation

- High-density kraft for load-bearing structures

② Structural Engineering (Packaging Engineering)

Based on product weight, fragility, and transportation method, the following are designed:

- Reinforced corners

- Double-wall structure

- Inner lining support

- Trays and partitions

③ Internal Protection System

Professional paper cushioning components include:

- Molded pulp pallets

- Corrugated partitions

- Paper card shockproof structure

- Custom die-cut positioning slots

These reduce shaking, prevent impacts, and significantly improve transportation safety.

④ Pre-production Testing

Failures often stem from:

- Paper material too thin

- Structure mismatch with transportation scenario

- No drop test/compression test performed

- Inaccurate dimensions

Small-batch trial production and testing can avoid these problems.

Are cardboard boxes truly environmentally friendly? The key lies in materials and processes.

The most frequently asked question by brands is: Are cardboard boxes truly recyclable and biodegradable?

The short answer: Yes, most paper materials are naturally recyclable, but the specific effectiveness depends on the surface treatment.

Highly recyclable paper materials

- Kraftpapier

- Weißer Karton

- C1S/C2S

- Corrugated paper

- Grey board

- Uncoated specialty paper

Processes that affect recycling (but have alternatives)

Processes that may reduce recyclability include:

- Lamination (glossy/frosted film)

- Large-area metallization

- Some UV processes

- Composite materials

The industry is now gradually adopting environmentally friendly alternatives:

- Water-based varnish

- Bio-based coatings

- Recyclable metal foil

- Soy-based ink printing

Satisfying visual appeal while maintaining environmental friendliness.

Why are cardboard boxes so advantageous in commercial applications?

Cardboard boxes not only offer advantages in protection and environmental protection, but also demonstrate extremely high value in brand presentation and supply chain costs.

Strong Visual Presentation and Brand Expression Capabilities

Paper boxes can achieve various printing and processing effects to meet brand tone requirements:

- CMYK Full Color

- Pantone Spot Colors

- Hot Stamping (Gold/Silver)

- Prägen/Entprägen

- Spot-UV-Lackierung

- Specialty Paper Materials

- Matte/Gloss Finishes

From minimalist to high-end, all can be easily achieved.

Suitable for Small and Large Batch Production (High Cost-Effectiveness)

Compared to plastic/wooden/metal boxes, paper boxes have significant advantages in production:

- Controllable Material Costs

- Mature Supply Chain and Stable Delivery Time

- Foldable Design Saves on Warehousing Costs

- Fast Prototyping

- Low Transportation Costs

Ideally ideal for startup brands, e-commerce brands, large factories, and trading companies making bulk purchases.

Widely Adaptable to Various Industries

Paper box applications include:

- Kosmetik & Hautpflege

- Jewelry & Accessories

- 3C Electronics

- Food & Beverages

- Coffee & Tea

- Apparel Packaging

- High-End Gifts

- E-commerce Shipping

Suitable for both brand retail and logistics transportation.

Why are paper boxes considered the packaging method with the “best overall value”?

In summary, the advantages of paper boxes include:

- Significant environmental value

- Sufficient structural protection

- Strong brand visual expression

- High cost-effectiveness

- Easy to mass-produce

- Lightweight, saving on transportation and warehousing costs

- Flexible customization

- Recyclable

Few materials combine so many advantages.

Yisheng: Providing Professional Customized Paper Box Solutions for Enterprises

Als professional paper packaging manufacturer, Yisheng provides one-stop customized and wholesale paper packaging services, covering multiple industries, materials, and process requirements.

Our product range includes:

- Rigid Gift Boxes

- Faltschachteln

- Corrugated Mailing Boxes

- Schubladenboxen

- Magnetic Boxes

- Specialty Paper Packaging

- Individuell gestaltete Papiertüten

- Custom packaging for food, cosmetics, jewelry, electronics, and apparel

Why Choose Yisheng?

① Eco-Friendly as Default: Standardized Environmentally Friendly Materials

We insist on prioritizing environmentally friendly options for all paper materials, balancing quality, durability, and brand sustainability goals.

② Stable Production Capacity & Sustainable Supply Chain

Mature production lines + complete quality inspection processes =

- Stable Production Capacity

- On-Time Delivery

- High Batch Consistency

Suitable for large-volume brands and trading companies.

③ Full-Size, Material, and Process Customization

Supports:

- Precise Mold Making

- Material Matching

- Packaging Structure Engineering

- Custom Surface Finishes (Hot Stamping, Embossing, etc.)

Ensuring packaging perfectly matches your brand image.

④ Cost-Effectiveness Optimization Strategy

We help companies achieve the optimal balance between brand presentation, cost budget, and structural performance.

Schlussfolgerung

It’s no accident that paper boxes have become the best packaging solution.

Their comprehensive performance in terms of environmental protection, cost, structure, visual appeal, and supply chain efficiency makes them one of the most cost-effective packaging materials today.

Through professional packaging structure design, appropriate paper material selection, and rigorous testing, brands can obtain packaging systems that are aesthetically pleasing, durable, and environmentally friendly.

Leveraging its strengths in customized packaging development, environmentally friendly material application, and end-to-end production management,

Yisheng is committed to helping global brands create paper packaging solutions that align with market trends, enhance product value, and strengthen brand image.