Custom jewelry boxes protect delicate pieces, elevate brand image, and control long-term packaging costs. This guide explains materials, structures, and cost factors to help brands design packaging that balances protection, presentation, and budget.

Why Custom Jewelry Boxes Matter

Jewelry may be small in size, but it carries high financial and emotional value. That makes packaging more than decorative—it must perform multiple roles at once.

Custom Jewelry Boxes help brands:

- Protect fragile items from scratches and damage

- Present jewelry in a premium, retail-ready way

- Reinforce brand positioning and perceived value

- Stay practical for storage, shipping, and display

Stock packaging rarely meets all these needs. Customization allows full control—but without understanding materials, structure, and cost, brands can easily overdesign and overspend.

Materials Used in Custom Jewelry Boxes

Paper-Based Materials as the Core Choice

Most Custom Jewelry Boxes rely on paper-based materials because they balance durability, sustainability, and cost efficiency.

Common options include:

- Greyboard (Chipboard):

A primary material for rigid jewelry boxes due to strength and dimensional stability. - White Cardboard / Kraft Board:

Often used for folding boxes and inner trays. - Specialty Paper:

Applied as surface wrapping to enhance texture, color, and print finish.

Paper materials are highly customizable, printable, and recyclable when sourced responsibly.

Environmental Considerations in Material Selection

Sustainability is now a top concern for jewelry brands and consumers alike.

Key eco-friendly factors include:

- Recycled paperboard

- Reduced plastic lamination

- Water-based inks and adhesives

Fully plastic-free Custom Jewelry Boxes are possible—but may increase costs or limit design flexibility. Many brands instead balance sustainability with functional performance.

Material Thickness and Protection

Thickness directly impacts both durability and budget.

- Thinner board: Lower cost, less protection

- Thicker board: Better rigidity, higher material and shipping cost

The right specification depends on jewelry weight, box size, and structure. Overspecifying materials often adds cost without practical value.

Structural Design of Custom Jewelry Boxes

Why Structure Matters as Much as Material

Even premium materials cannot compensate for poor structure. Structural design determines:

- Protection strength

- Opening experience

- Assembly efficiency

- Shipping and storage space

Well-engineered Custom Jewelry Boxes enhance both function and brand perception.

Common Jewelry Box Structures

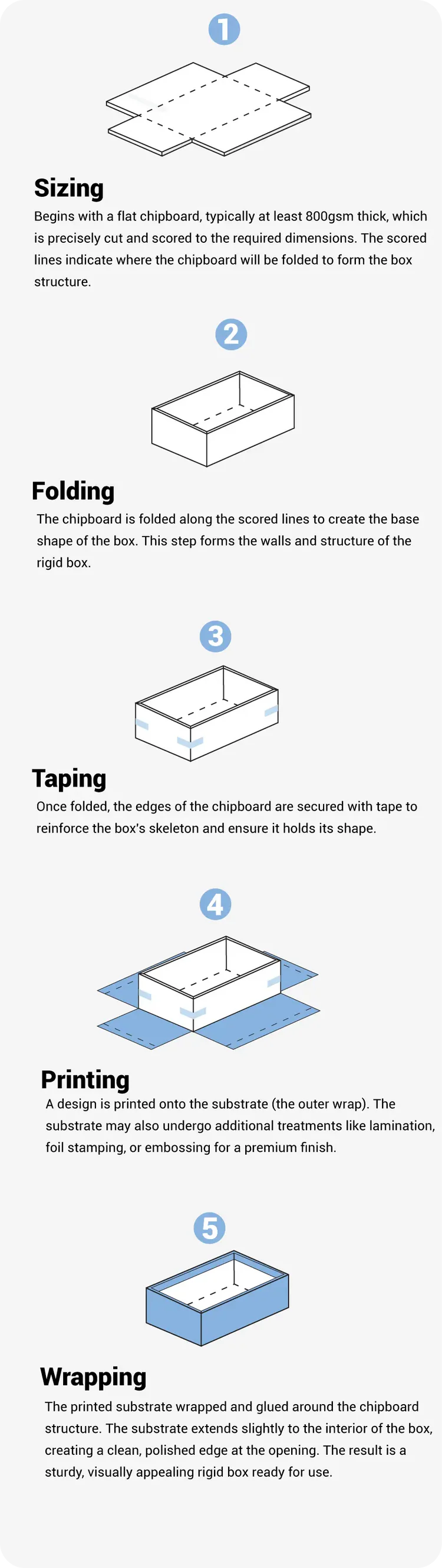

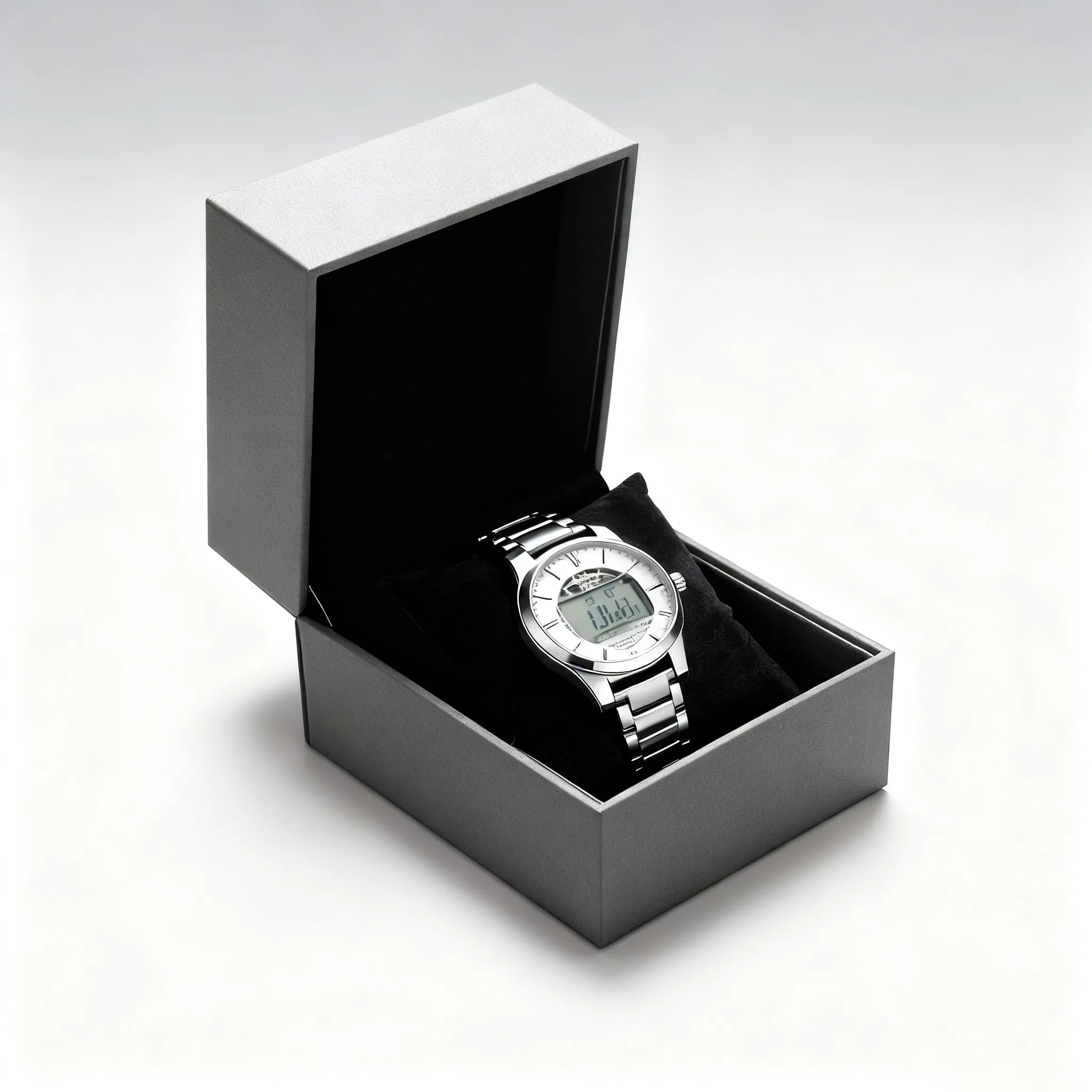

Rigid Lift-Off Lid Boxes

Simple two-piece boxes with a separate lid and base.

Преимущества:

- Excellent protection

- Classic premium look

- Ideal for rings and necklaces

Limitations:

- Occupies more storage space

- Higher shipping volume

Well-engineered Custom Jewelry Boxes enhance both function and brand perception. Many premium designs are built using rigid structures. If you want to explore structural variations in depth, you can refer to our guide for a comprehensive overview.

Коробки с магнитными крышками

A luxury packaging choice for high-end jewelry lines.

Преимущества:

- Premium unboxing experience

- Reusable and durable

Limitations:

- Higher material and labor cost

- Added weight from magnets

Drawer (Sliding) Jewelry Boxes

A layered structure that enhances presentation.

Преимущества:

- Strong protection

- Memorable unboxing feel

Limitations:

- Complex tooling

- Higher assembly cost

Internal Structure and Inserts

The interior of Custom Jewelry Boxes is critical for securing products.

Common insert materials:

- Paperboard wrapped in velvet or paper

- Molded pulp inserts

- Foam inserts

Foam offers superior cushioning but may conflict with sustainability goals. Insert selection should balance protection, eco targets, and cost.

Cost Breakdown of Custom Jewelry Boxes

Material Cost

Driven by:

- Board type and thickness

- Surface paper

- Insert materials

Premium papers and thicker boards increase cost but elevate brand perception.

Structure & Tooling Cost

Complex structures require additional dies and molds.

- Drawer boxes → Higher tooling cost

- Magnetic boxes → Higher material + labor cost

- Lift-off boxes → More cost-efficient

Printing & Finishing Cost

Decorative processes significantly impact pricing:

- Foil stamping

- Embossing / debossing

- Spot UV

Selective use enhances branding without inflating budgets.

Assembly & Labor Cost

Handmade rigid Custom Jewelry Boxes cost more than foldable cartons. Complexity and insert design directly affect labor expense.

Logistics & Shipping Cost

Heavier, rigid boxes increase freight cost. Flat-pack designs save logistics expense but limit structural options.

Common Challenges in Custom Jewelry Box Production

Balancing Sustainability & Performance

Eco materials may lack strength or luxury finish.

Решения:

- Recycled greyboard + premium wrap paper

- Reduce plastic instead of eliminating it

- Focus on recyclability

Ensuring Structural Strength

Jewelry must stay protected through shipping and handling.

Решения:

- Reinforced edges and corners

- Structure matched to jewelry weight

- Drop and compression testing

Controlling Cost Without Sacrificing Quality

Customization can escalate costs quickly.

Решения:

- Standardize box sizes

- Limit luxury finishes

- Optimize board thickness

Maintaining Order Consistency

Inconsistent color or structure affects brand image.

Решения:

- Approve pre-production samples

- Use stable suppliers

- Lock material specifications

Matching Jewelry Type to Box Design

Different products require different Custom Jewelry Boxes:

- Rings: Small rigid boxes with secure inserts

- Necklaces: Drawer or magnetic boxes with hooks

- Earrings: Lightweight rigid or folding boxes with display cards

Proper matching avoids over-packaging and controls cost.

Customization Options That Add Real Value

Value-driven customization focuses on branding and usability.

Effective options:

- Custom dimensions

- Logo placement

- Functional inserts

Less effective options:

- Excessive decorative elements

- Non-functional add-ons

Why Manufacturing Experience Matters

Experienced manufacturers ensure Custom Jewelry Boxes meet both design and production realities.

They help brands:

- Optimize structures for mass production

- Reduce unnecessary costs

- Maintain consistent quality

Why Choose Yisheng for Custom Jewelry Boxes

Упаковка Yisheng, founded in 2008, is a professional custom packaging box manufacturer specializing in wholesale and custom solutions.

We provide flexible packaging services across:

- Luxury gift boxes

- Бумажные коробки

- Бумажные пакеты

- Paper-plastic boxes

Material Expertise

We offer diverse paperboard options aligned with sustainability and durability goals.

Structural Customization

From rigid to magnetic and drawer-style Custom Jewelry Boxes, we tailor structures to jewelry types.

Controlled Production

Advanced equipment ensures precision, stable quality, and reliable lead times.

Cost-Aware Design Support

We guide brands toward cost-performance balance without unnecessary complexity.

Scalable Wholesale Capacity

From small custom runs to large-volume orders, Yisheng supports long-term growth.

FAQ: Custom Jewelry Boxes

1. What materials are best for Custom Jewelry Boxes?

Greyboard with specialty paper wrapping is the most common for rigid luxury boxes, balancing strength and branding.

2. Are Custom Jewelry Boxes eco-friendly?

They can be. Using recycled paperboard, water-based inks, and minimal plastic improves sustainability.

3. Which structure is most cost-effective?

Rigid lift-off lid boxes offer strong protection at a relatively moderate cost compared to magnetic or drawer styles.

4. Do inserts really matter?

Yes. Inserts prevent movement, protect jewelry, and enhance presentation.

5. How can I reduce packaging costs?

Standardize sizes, simplify finishes, and optimize material thickness.

Заключение

Custom Jewelry Boxes go far beyond aesthetics. Materials, structure, and cost must work together to protect jewelry, express brand value, and remain commercially viable.

With the right design strategy—and the right manufacturing partner—brands can achieve packaging that is protective, premium, and cost-efficient.

Partner with Yisheng Packaging to develop Custom Jewelry Boxes that balance luxury presentation with practical production performance. We welcome collaborations for wholesale and custom projects tailored to your brand’s unique needs.