In luxe packaging, Rigid Box packaging is regarded as the best solution for brands that wish to convey one message, presentation, protection and ultimately the same message of the brand to the end user. Rigid boxes are sales tools that increase perceived value, whether it’s luxury cosmetics, consumer electronics or giftware.

For the B2B buyers, brand owners and sourcing managers, the knowledge about the various kinds of rigid boxes, their structures, features, and applications is a must when considering designing your own box or buying boxes in bulk.

This post outlines the most popular rigid boxes styles, highlighting their differences and helping you determine the right one for your business and product.

What Is a Rigid Box?

A Rigid Box (also known as a set-up box) is made from thick paperboard—typically 800gsm to 2000gsm—and wrapped with printed or decorative paper. Unlike folding boxes, rigid boxes are pre-assembled and non-collapsible, giving them superior strength and a premium feel.

Key advantages of rigid box packaging include:

- Excellent structural strength and protection

- Premium, gift-worthy appearance

- Strong support for luxury branding

- Compatibility with custom inserts and complex structures

Common Types of Rigid Boxes by Structure

1. Magnetic Closure Rigid Box

Structure:

A hinged lid with built-in magnets that create a smooth, secure closure.

Key Features:

- Clean, modern opening experience

- Strong closure without visible fasteners

- Ideal for branding with foil stamping or embossing

Best Uses:

- Luxury cosmetics and skincare sets

- Electronics and accessories

- Corporate gifts and promotional kits

2. Drawer Rigid Box (Slide Box)

Structure:

An outer sleeve with an inner drawer that slides out, often paired with a ribbon pull.

Key Features:

- Interactive unboxing experience

- Excellent internal organization

- Suitable for multi-component products

Best Uses:

- Jewelry and watches

- Premium confectionery

- Gift boxes with multiple items

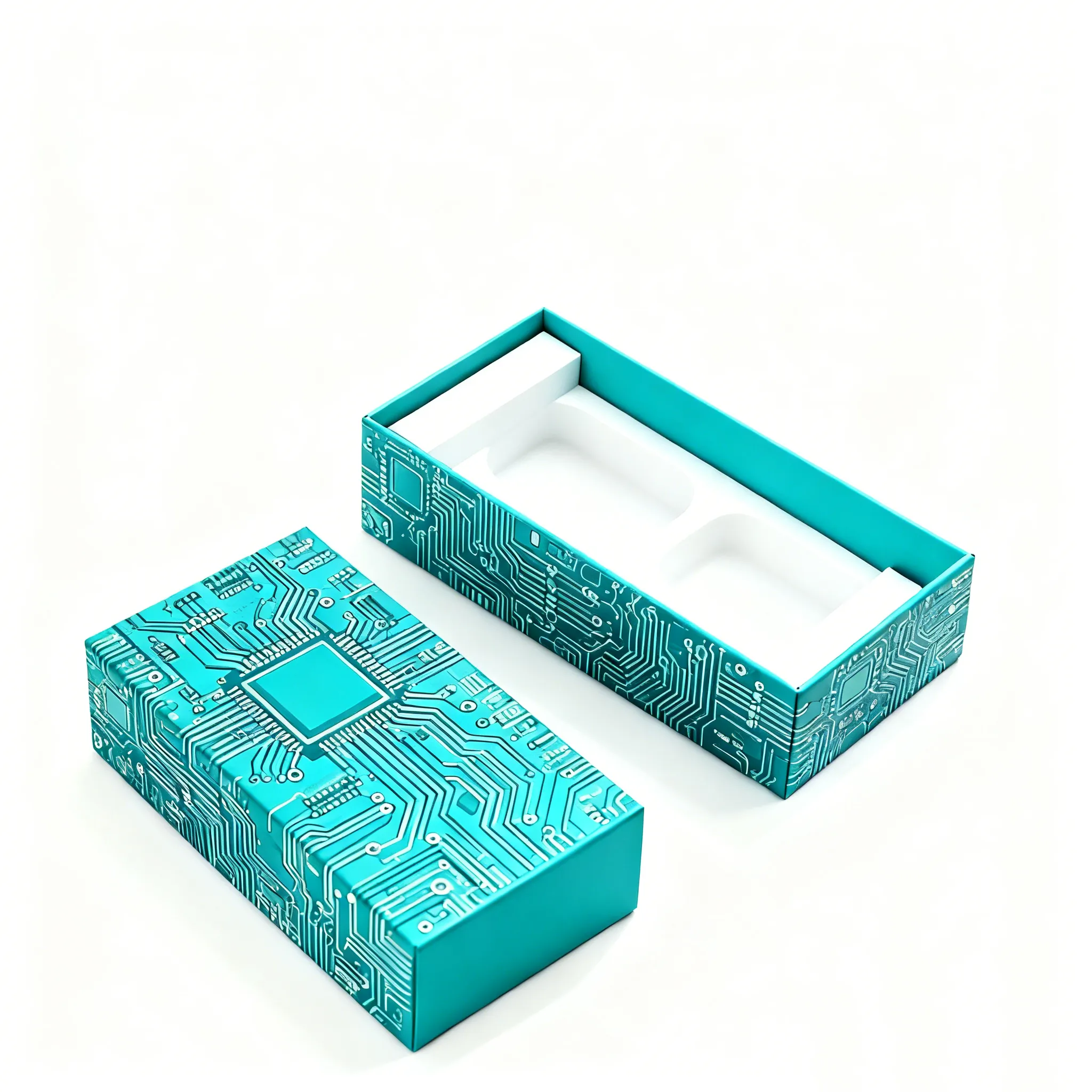

3. Lift-Off Lid Rigid Box (Two-Piece Box)

Structure:

Consists of a separate lid and base; the lid lifts off completely.

Key Features:

- Classic and cost-effective rigid box structure

- Simple design with strong durability

- Easy to customize with printing and wrapping paper

Best Uses:

- Apparel and fashion accessories

- Luxury food packaging

- General-purpose premium packaging

4. Shoulder / Neck Rigid Box

Structure:

Includes a visible or hidden inner frame (shoulder) between the lid and base.

Key Features:

- Enhanced structural strength

- Refined, layered appearance

- Allows partial lid exposure for premium aesthetics

Best Uses:

- Perfume and fragrance packaging

- High-end electronics

- Collectible or limited-edition products

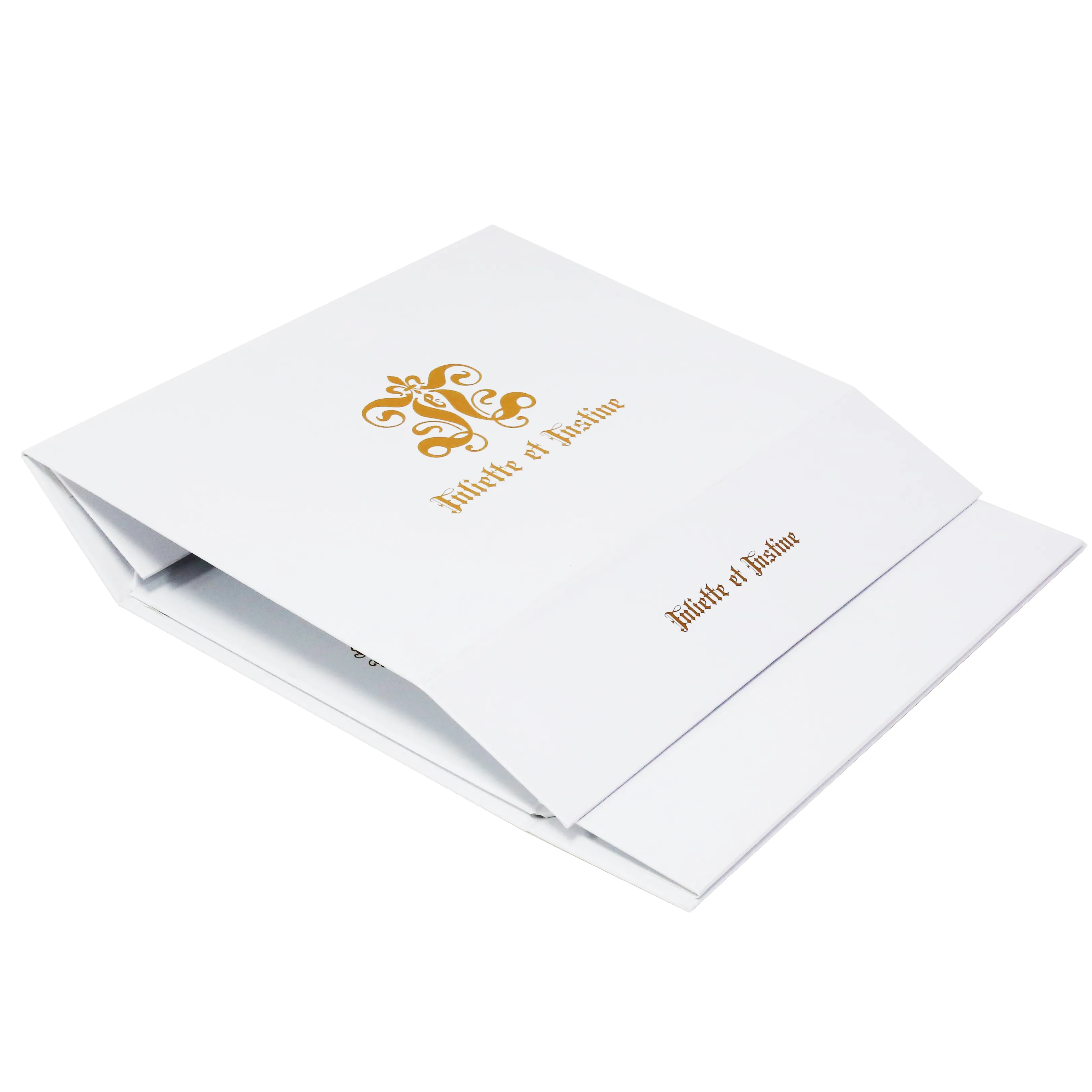

5. Book-Style Rigid Box

Structure:

Opens like a book with a hinged side and magnetic or ribbon closure.

Key Features:

- Large branding area inside and outside

- Storytelling-friendly design

- Ideal for presentation-focused products

Best Uses:

- Luxury gift sets

- Brand launch kits

- High-end promotional packaging

6. Collapsible Rigid Box

Structure:

A rigid box with foldable panels and hidden magnetic corners, allowing it to collapse flat when not in use.

Key Features:

- Premium look with reduced storage volume

- Lower shipping and warehousing costs

- Ideal for large-scale distribution

Best Uses:

- E-commerce luxury packaging

- Seasonal promotions

- Brands balancing luxury and logistics efficiency

Rigid Box Types vs Product Applications

| Product Category | Recommended Rigid Box Types |

|---|---|

| Cosmetics & Skincare | Magnetic, Book-Style |

| Jewelry & Watches | Drawer, Shoulder |

| Electronics | Magnetic, Shoulder |

| Luxury Food & Gifts | Lift-Off Lid, Drawer |

| Promotional Kits | Book-Style, Collapsible |

Customization Options for Rigid Boxes

Rigid box packaging supports extensive customization, making it ideal for OEM and ODM projects.

Common Custom Options Include:

- Board thickness and box size

- CMYK or Pantone printing

- Surface finishes: matte, gloss, soft-touch lamination

- Decorative processes: foil stamping, embossing, debossing, spot UV

- Inserts: paperboard, molded pulp, corrugated, EVA alternatives

These options allow brands to fine-tune cost, protection, and visual impact.

How to Choose the Right Rigid Box Type

When selecting a rigid box structure, B2B buyers should evaluate:

- Product weight and fragility – heavier or delicate items require stronger structures and inserts

- Brand positioning – luxury brands benefit from magnetic or book-style boxes

- Unboxing experience – drawer and book-style boxes enhance interaction

- Logistics and storage – collapsible rigid boxes reduce freight costs

- Budget and order volume – lift-off lid boxes offer a cost-efficient premium solution

Rigid Box vs Folding Box: A Quick Reminder

While rigid boxes offer superior protection and premium presentation, they require more storage space and higher unit costs compared to folding boxes. Many brands combine both formats—for example, a folding outer carton with a rigid inner tray—to balance cost and performance.

About Yisheng – Custom Rigid Box Manufacturer

Yisheng is a professional paper packaging manufacturer specializing in custom and wholesale rigid box packaging.

We support:

- Multiple rigid box structures

- Flexible OEM & ODM customization

- Sustainable and recyclable material options

- Stable quality for mass production

From design consultation to bulk manufacturing, Yisheng helps brands create rigid box packaging that protects products, enhances brand value, and supports efficient supply chains.

Conclusion

Different types of rigid boxes serve different branding and functional needs. By understanding box structures, features, and best-use scenarios, brands can make smarter packaging decisions that balance aesthetics, protection, cost, and logistics.

Whether you need a classic lift-off lid box or an advanced magnetic or collapsible rigid box, choosing the right structure ensures your packaging works as a powerful extension of your brand.