In custom paper packaging, clear and definite custom packaging requirements are the way to supply the right product. Most customers, though, especially new ones or those not knowledgeable about materials and processes, have no clue how to articulate their requirements clearly. What follows is delay, several revisions, or dissatisfaction with the output.

At Yisheng, we deal with these issues on a regular basis, especially with overseas clients. In this blog, we’ll discuss why ambiguous requirements occur, how they impact production, and what practical solutions both manufacturers and customers can undertake to close the communication gap.

Why Do Customers Struggle to Provide Clear Custom Packaging Requirements?

- Vague Descriptions Without Visual References

Terms like “luxury,” “premium,” or “eco-friendly” are highly subjective. Without photos or samples, these words can mean very different things to different people. One client’s “high-end” may involve gold foil stamping, while another imagines a minimal matte black finish. Without clear visual references, it’s nearly impossible to interpret these custom packaging requirements accurately.

- Limited Knowledge of Materials and Techniques

Many buyers are unfamiliar with:

- Paper types: kraft paper, coated paper, art paper, etc.

- Printing/finishing: hot stamping, spot UV, embossing, lamination

This knowledge gap makes it difficult to choose the right material or method for the product’s purpose and budget.

- Language and Cultural Barriers

Subtle differences in preference and meaning often get lost in translation. For example, “simple” might mean “minimalist” to one client but “bright and clean” to another, making it difficult to align custom packaging requirements across borders.

- Unclear or Incomplete Design Files

Design files may arrive in the wrong format, with low resolution, missing bleed areas, or unembedded fonts, causing delays and revisions.

How Unclear Requirements Impact the Packaging Process

Vague or inconsistent custom packaging requirements can affect the entire production timeline:

- Delays: Extended back-and-forth communication slows down timelines.

- Higher Costs: Reworking samples and changing specs increases expenses.

- Lower Satisfaction: The final product may not meet expectations.

- Material Waste: Incorrect designs or bulk orders that need redoing waste both resources and money.

How Yisheng Helps Clients Define Custom Packaging Requirements Clearly

As a flexible, small-scale packaging manufacturer, Yisheng doesn’t rely on automated design tools. Instead, we offer hands-on, human support to help every client clarify their custom packaging requirements step by step.

- Detailed Requirement Checklist

We help customers organize their ideas through a practical checklist that includes:

- Box type and structure (rigid, tuck-end, drawer, etc.)

- Product size and weight

- Intended use (food, gift, cosmetics, etc.)

- Material preferences and environmental concerns

- Finishing options (foil, embossing, lamination, etc.)

This simplifies complex custom packaging requirements into clear choices.

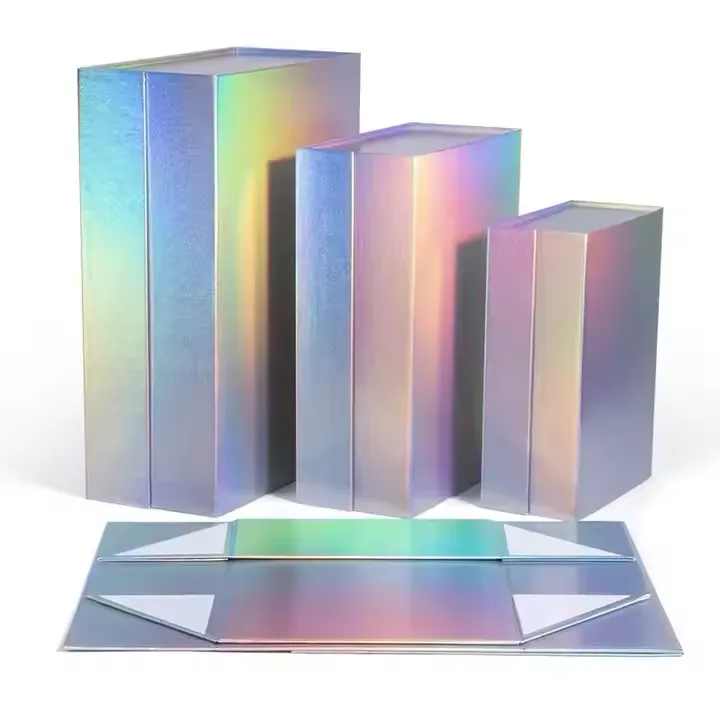

- Real Photos and Video Examples

We share photos and videos of past projects to demonstrate real results. Clients can see how different finishes reflect light or how paper textures feel, bridging the gap between imagination and execution.

- Paid Sample Services

To reduce risk and ensure clarity, we offer paid small-batch samples so customers can test the material, print quality, and structure before bulk production.

- Visual Communication Tools

Instead of lengthy text emails, we prefer:

- Annotated PDFs

- Product photos

- Step-by-step video walkthroughs

This visual-first approach improves understanding, especially for clients with limited design or English skills.

- Long-Term Customer Profiles

For repeat customers, we maintain records of:

- Past orders

- Preferences

- Feedback

This helps streamline future orders and eliminate repeated clarification of custom packaging requirements.

Tips for Customers: How to Prepare Clear Requirements

To make the process smoother, we suggest customers follow these steps:

- Use Visual References

Send images from Pinterest, competitor brands, or rough sketches to illustrate desired style, color, and layout. - Provide Exact Product Dimensions

Accurate internal and external measurements ensure the box fits and functions properly. - Share Budget and Order Quantity Early

These factors affect material choice and finishing options. Sharing them helps us suggest solutions that fit both style and budget. - Don’t Be Afraid to Ask

We encourage clients to ask questions about materials, finishes, and production processes to avoid confusion. - Be Open to Expert Advice

We often recommend more practical or cost-effective alternatives without compromising quality or branding.

Real Case Studies

Case 1: Misunderstood “Eco-Friendly” Packaging

A client requested “eco-friendly” packaging, but didn’t specify further. Through discussion and samples, we clarified they wanted recycled kraft paper without plastic lamination—saving time and avoiding rework.

Case 2: Language Barrier Over Matte Finish

A European client had trouble describing the desired finish. We provided annotated images and videos comparing matte vs. satin lamination. The client quickly chose matte, speeding up the production timeline.

Small Manufacturer, Big Communication Advantage

Although Yisheng isn’t a large-scale automated factory, our strength lies in personalized service:

- Customized checklists and visual catalogs help reduce guesswork.

- Paid sampling enables customers to experience quality firsthand.

- Clear communication through images and video bridges language gaps.

- Building trust through ongoing relationships makes future orders smoother.

Conclusion: Make Communication Clearer, Make Customization Easier

In the world of custom packaging, unclear initial requirements are a common challenge, especially for first-time buyers or clients without design backgrounds. But through clear communication, visual references, and step-by-step support, vague ideas can be transformed into professional, high-quality packaging.

At Yisheng, we go beyond just “making boxes.” We help customers shape their brand image through thoughtful, tailored packaging solutions—step by step. As a flexible and service-focused small-scale packaging manufacturer, we offer hands-on experience and responsive communication to turn your ideas into reality, even if you’re not a designer.

About Yisheng

Yisheng is a dedicated paper packaging manufacturer offering custom solutions for paper boxes, gift bags, food containers, and more. Our products serve jewelry, cosmetics, food, gifts, and various other industries. We provide full support for custom designs and sample production, delivering one-stop services from concept to delivery. Our goal is to create packaging that’s not only functional and visually appealing but also tailored to your market needs and sustainable in the long term.

Need help with your custom packaging requirements? Contact Yisheng—we make custom simple.