In today’s competitive market, packaging is more than just protection—it is a key part of brand identity. For brands in the food, bakery, cosmetics, and gift industries, OEM paper gift boxes have become a popular solution to achieve high-quality, customized packaging while keeping production efficient and cost-effective.

This article explains what OEM paper gift box processing is, how the manufacturing process works, and what businesses should consider when choosing a reliable OEM packaging manufacturer.

What Is OEM Paper Gift Box?

OEM (Original Equipment Manufacturer) paper gift box service refers to a manufacturing model where a professional packaging factory produces paper gift boxes based on the client’s specifications, designs, and branding requirements.

In an OEM paper gift box project:

- The brand owner provides the box design, size, logo, and requirements.

- The manufacturer focuses on material sourcing, printing, production, and quality control.

- The final product is delivered under the client’s brand name.

This model is widely used by B2B buyers because it allows brands to focus on marketing and sales while relying on an experienced factory for consistent quality and scalable production.

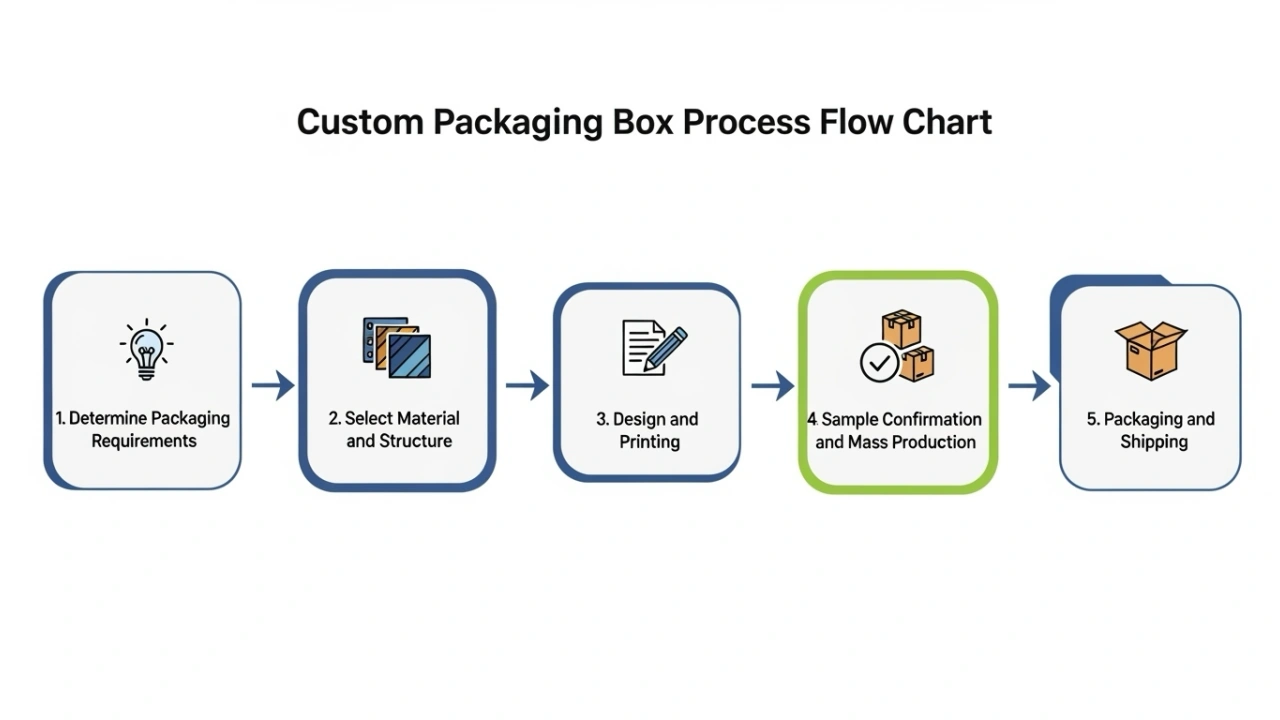

OEM Paper Gift Box Processing: Step-by-Step Overview

Understanding the OEM processing flow helps buyers communicate more efficiently with manufacturers and avoid costly mistakes. Below is a typical OEM paper gift box processing workflow.

1. Requirement Confirmation

The process starts with a detailed discussion of the buyer’s needs, including:

- Box size and structure

- Application (gift, food, bakery, cosmetics, etc.)

- Target market and positioning

- Order quantity and delivery timeline

At this stage, clients may provide design files or reference samples for the OEM paper gift box.

2. Material and Structure Selection

Choosing the right material is critical for both appearance and performance. Common materials for paper gift boxes include:

- 白い厚紙 – smooth surface, ideal for premium printing

- Kraft paper – natural look, often used for eco-friendly packaging

- Grey board paper – strong and durable, suitable for rigid gift boxes

The box structure (folding box, rigid box, magnetic closure box, drawer box, etc.) is also confirmed during this stage.

3. Printing and Surface Finishing

Printing quality plays a major role in brand perception. OEM paper gift box manufacturers typically offer:

- Offset printing for high-resolution graphics

- UV printing for enhanced color and durability

Surface finishing options include:

- 箔押し

- Embossing or debossing

- Matte or glossy lamination

- Spot UV coating

These processes help enhance the visual appeal and premium feel of the paper gift box.

4. Die Cutting, Forming, and Assembly

After printing, the paper sheets are die-cut and formed according to the box structure. This stage combines:

- Automated machinery for precision and efficiency

- Manual assembly for complex structures and detailed finishing

Strict quality control is applied to ensure consistent size, clean edges, strong adhesion, and overall durability.

5. Packaging and Delivery

Once the OEM paper gift boxes are completed, they are carefully packed to prevent damage during transportation. Manufacturers may offer:

- Flat-packed or pre-assembled delivery

- Export-standard cartons

- Support for bulk shipment or phased delivery

This ensures the boxes arrive safely and ready for use.

Why OEM Paper Gift Boxes Add Value to Your Brand

Custom paper gift boxes are not just packaging—they are a marketing tool. A well-designed OEM paper gift box can:

- Strengthen brand recognition

- Improve product presentation and perceived value

- Enhance the unboxing experience

- Support seasonal promotions and gift campaigns

For industries such as bakery, food, and cosmetics, packaging often influences purchasing decisions as much as the product itself.

How to Choose the Right OEM Paper Gift Box Manufacturer

When selecting an OEM partner, B2B buyers should consider the following factors:

- Manufacturing capability: Complete production lines and stable output capacity

- Quality control system: Clear inspection standards and consistent quality

- Customization flexibility: Support for different materials, sizes, and finishing options

- Communication efficiency: Professional service, fast response, and clear documentation

Choosing the right manufacturer helps reduce risks and ensures long-term cooperation.

Why Choose Yisheng for OEM Paper Gift Box Processing

イーシェン is a professional packaging box manufacturer specializing in OEM paper gift box production and wholesale customization. We provide a wide range of packaging solutions, including paper boxes, paper-plastic boxes, gift boxes, food packaging boxes, bakery packaging boxes, and paper bags.

With advanced production equipment, experienced technicians, and a complete quality control system, Yisheng supports OEM projects from sampling to mass production. Our packaging solutions are widely used in the food, bakery, gift, and cosmetics industries and are exported to multiple international markets.

If you are looking for a reliable OEM paper gift box manufacturer with stable quality and flexible customization options, Yisheng is ready to support your packaging needs.