Les conception d'emballages va au-delà d'une belle image dans le marché concurrentiel d'aujourd'hui ; c'est une interprétation holistique de la communication de la marque, de la protection du produit et de la puissance du marketing. Un processus d'emballage peut rehausser votre produit, transmettre la valeur de votre marque et enrichir l'expérience globale du consommateur, de la première vue au déballage.

Afin d'aider les entreprises à concevoir des emballages personnalisés de manière plus efficace et plus cohérente, cet article présente les sept étapes essentielles de la conception d'un emballage et fournit des solutions concrètes pour répondre aux besoins de la boîte d'emballage en papier.

Définir l'objectif et le positionnement de la marque

Avant d'entamer tout processus de conception, vous devez définir clairement vos objectifs et la position de votre marque. Avant même de songer à effectuer un travail de conception, vous devez apporter des réponses très claires aux questions suivantes :

- Quel est votre groupe de consommateurs cible ?

- Quel est le ton de votre marque (luxe, écologique, minimaliste, économique) ?

- Quels sont vos canaux de vente ? (E-commerce, commerce de détail, cadeaux)

- Quelles sont les principales fonctions de l'emballage ? (Protection, présentation, amélioration de l'expérience de déballage)

- Budget, délais de livraison, contraintes de production ?

- S'agit-il de protection de l'environnement ou de réglementations industrielles ?

Sans une définition claire à ce stade, les conceptions structurelles et visuelles ultérieures de l'emballage risquent de s'égarer.

Effectuer des études de marché et de concurrence

L'étude de marché et l'analyse de la concurrence font de votre conception d'emballages “différencié mais raisonnable”. Une excellente conception n'est pas le fruit d'un travail isolé ; elle s'appuie sur les données du marché.

Ce que vous devez faire :

- Analyser les structures, les matériaux, le langage visuel et les techniques décoratives des concurrents.

- Étudier les tendances de consommation : emballage durable, protection du commerce électronique, minimalisme, etc.

- Comparer les exigences en matière d'emballage pour les différents canaux de vente.

- Recueillir les expériences réelles des utilisateurs : expérience de déballage, protection et performances d'expédition.

Problèmes courants :

- Poursuivre uniquement l'esthétique sans s'aligner sur le positionnement du marché.

- Suivre aveuglément les tendances conduit à une augmentation des coûts ou à des difficultés de production.

- Manque de différenciation.

Solutions :

- Prélever des échantillons de concurrents.

- Dressez la liste des lacunes au niveau des matériaux, de la forme du gobelet, de la structure et du prix unitaire.

- Établissez une “matrice de différenciation” pour définir clairement les avantages de votre marque en matière d'emballage.

Déterminer la structure et la fonctionnalité

La conception structurelle est la logique sous-jacente de la conception d'un emballage ; une belle conception graphique ne peut pas compenser une structure défectueuse. C'est pourquoi vous devez donner la priorité à la détermination :

- Type de boîte : tiroir, couvercle supérieur et inférieur, boîte pliante, sac en papier, etc.

- Épaisseur du matériau : poids du carton, épaisseur du carton gris, type de carton ondulé

- Structure de soutien interne : EVA, bacs à papier, fentes pour cartes, structure en nid d'abeille, etc.

- Exigences en matière de transport : l'empilabilité, la résistance à l'humidité et la résistance à la pression.

Toutes les conceptions structurelles aboutiront en fin de compte à une dieline, et la fonctionnalité de sa conception d'emballage sera testée à l'aide d'échantillons.

Pratiques recommandées :

- Finaliser la conception de la découpe le plus tôt possible.

- Épreuve 1 à 3 fois pour tester la protection réelle et la sensation structurelle.

- Communiquer avec l'usine pour trouver la solution matérielle la plus économique et la plus réalisable.

Développer la conception visuelle et graphique

La conception visuelle fait passer la conception de l'emballage de la fonction à l'expression de la marque. Après confirmation de la structure, il faut commencer à concevoir les éléments graphiques et visuels de la marque :

- Placement et proportion du logo

- Typographie et palette de couleurs

- Illustrations, motifs et éléments photographiques

- Mise en page des codes-barres et des informations de conformité

- Procédés : Marquage à chaud, vernissage UV, gaufrage, pelliculage, etc.

Les pièges les plus fréquents :

- Incohérence entre l'effet 3D et le produit final

- Différence de couleur, absorption de l'encre par les matériaux et éclairage entraînant des divergences dans l'effet final.

Solutions pratiques :

- Rendu 3D + maquette virtuelle pour confirmation du client

- Imprimer des échantillons de couleurs pour tester les vraies couleurs de différents matériaux papier

- Communiquer avec le fournisseur au sujet des écarts de couleur acceptables.

Choisir les matériaux et les techniques de finition

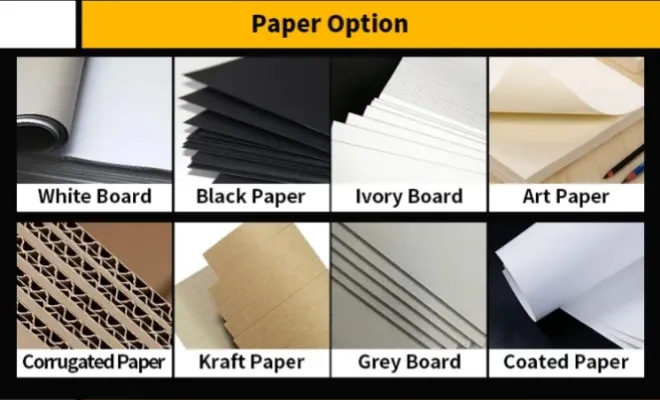

Les matériaux et les procédés déterminent la texture et le coût des boîtes d'emballage en papier. Papiers courants :

- Carton gris + papier de montage (rigide) Boîte

- Carton blanc, papier couché (boîte pliante)

- Papier kraft, papier recyclé (écologique)

- Carton ondulé (adapté au transport)

Processus communs :

- Marquage à chaud

- Gaufrage/Débossage

- Vernis UV par points

- Lamination mate/brillante

- Clips magnétiques, rubans, fenêtres, etc.

Notes :

- La multiplication des processus entraîne une augmentation des coûts.

- Certains processus peuvent affecter la recyclabilité.

- Il est nécessaire de s'assurer au préalable auprès du fournisseur qu'il dispose de l'équipement correspondant.

Prototype et perfectionnement

Un prototype est essentiel pour transformer conception d'emballages dans la réalité. L'étape de l'échantillonnage permet de vérifier :

- L'adéquation entre la structure et le produit

- Si la résistance du matériau est suffisante

- Les couleurs d'impression sont-elles exactes ?

- Si les processus et les positions sont corrects

- Si l'ouverture et la fermeture se font en douceur.

Recommandations :

- Prévoir au moins 1 à 2 itérations de prototypage.

- Établir une liste de contrôle claire.

- Enfin, confirmer que l'échantillon est un “échantillon standard de production de masse”.

Production et contrôle de la qualité

La production de masse et le contrôle de la qualité sont des points de contrôle clés qui garantissent la stabilité de la production de chaque boîte d'emballage en papier :

- Production d'essais en petites séries et étalonnage des couleurs

- Précision de la coupe, du rainurage et du collage

- Cohérence de l'estampage à chaud, du laminage et d'autres processus

- Contrôle par échantillonnage de lots

- Conditions de transport et de stockage (protection contre l'humidité, protection contre la pression, prévention des déformations)

Risques et solutions :

- Différence de couleur entre les lots → Exiger “les 500 premières productions de masse confirmées”.”

- Différents lots de papier → Établir des spécifications détaillées pour les matériaux et les processus de fabrication du papier

- Incohérences dans les commandes en double → Préserver strictement les documents de production et les échantillons

À propos de Yisheng - Votre partenaire professionnel en matière d'emballage en papier

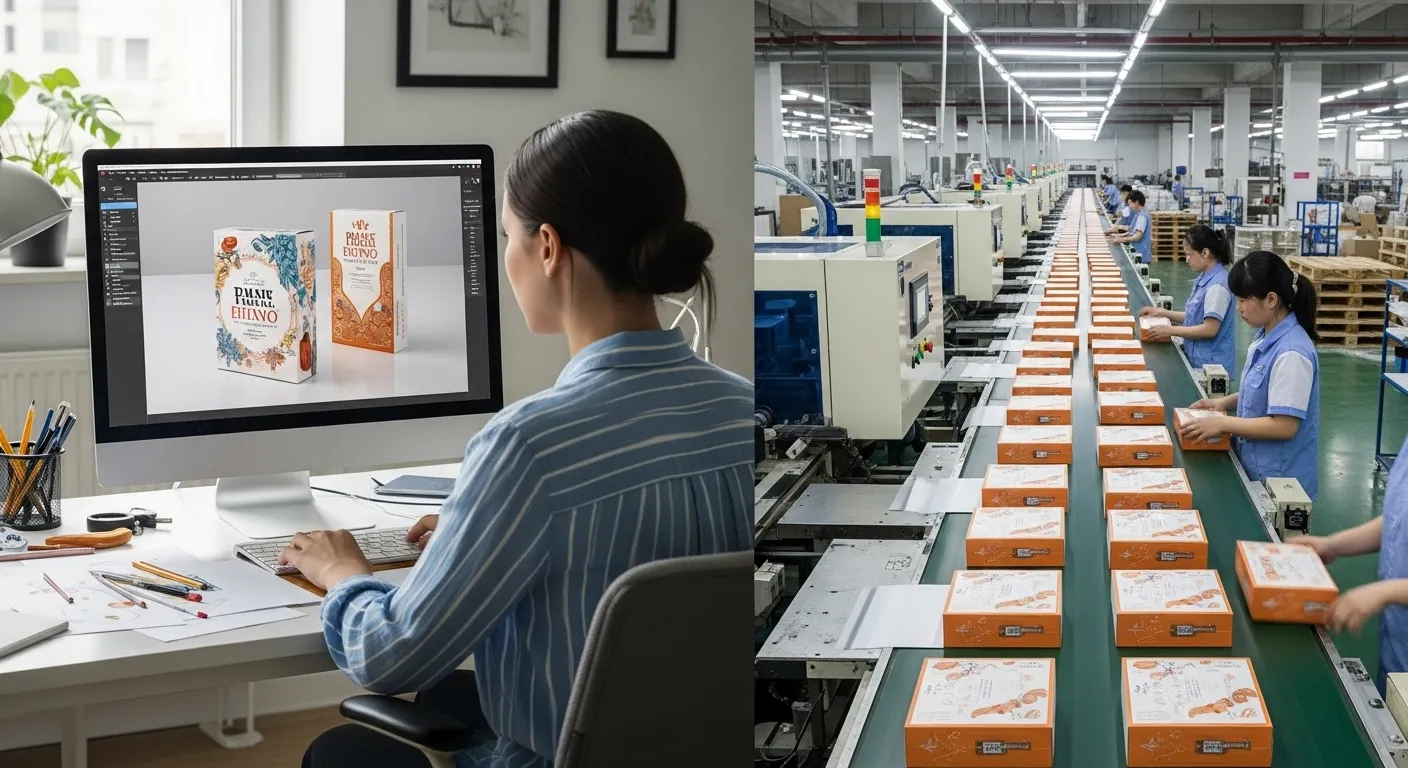

Yisheng est un professionnel emballage en papier fabricant de boîtes, fournissant des solutions complètes pour la personnalisation et la vente en gros, y compris la conception structurelle, la sélection des matériaux, la personnalisation des processus, le prototypage, la production en série et la logistique.

Pourquoi choisir Yisheng ?

- Nombreuses options de personnalisation : Qu'il s'agisse de boîtes-cadeaux rigides, de boîtes à tiroirs, de boîtes pliantes ou de sacs en papier haut de gamme, nous pouvons tous les produire de manière professionnelle.

- Entièrement personnalisé en fonction de vos besoins : Les matériaux, l'impression, les dimensions et la structure sont tous adaptés aux exigences de votre marque.

- Doté d'équipements de production modernes : Garantir une qualité constante et une livraison rapide.

- Les matériaux durables d'abord : Soutenir le papier FSC, les encres respectueuses de l'environnement et les structures recyclables.

- Communication claire + collaboration souple : Il convient aux entreprises en phase de démarrage, aux commandes de petites quantités et à la production de masse à grande échelle.

Conclusion : La conception de l'emballage au service de votre marque

Que vous créiez un nouvel emballage pour un produit ou que vous redéfinissiez l'image de votre marque, un processus de conception d'emballage clair peut réduire les retouches, les coûts de communication et garantir que chaque détail reflète la valeur de votre marque.

Yisheng est prêt à vous fournir solutions d'emballage en papier pour aider votre marque à obtenir une expérience d'emballage plus professionnelle et de meilleure qualité.