Packaging changes the way of think about your product. From cosmetics and electronics to fashion accessories and food and gift packaging, the right paper box does more than protect the product – it communicates brand equity, adds appeal on the shelf and contributes to the overall consumer experience.

Out of all the packing styles, Boîte rigide et Boîte pliante are the top two options used in b2b packaging. Although the two products have the identical basic aim, they vary wildly in structure, cost, logistics, branding impact, and end-user experience.

This blog is for those B2B buyers, brand owners, wholesalers, and sourcing managers who want to choose the right box solution for wholesale, OEM or custom packaging service.

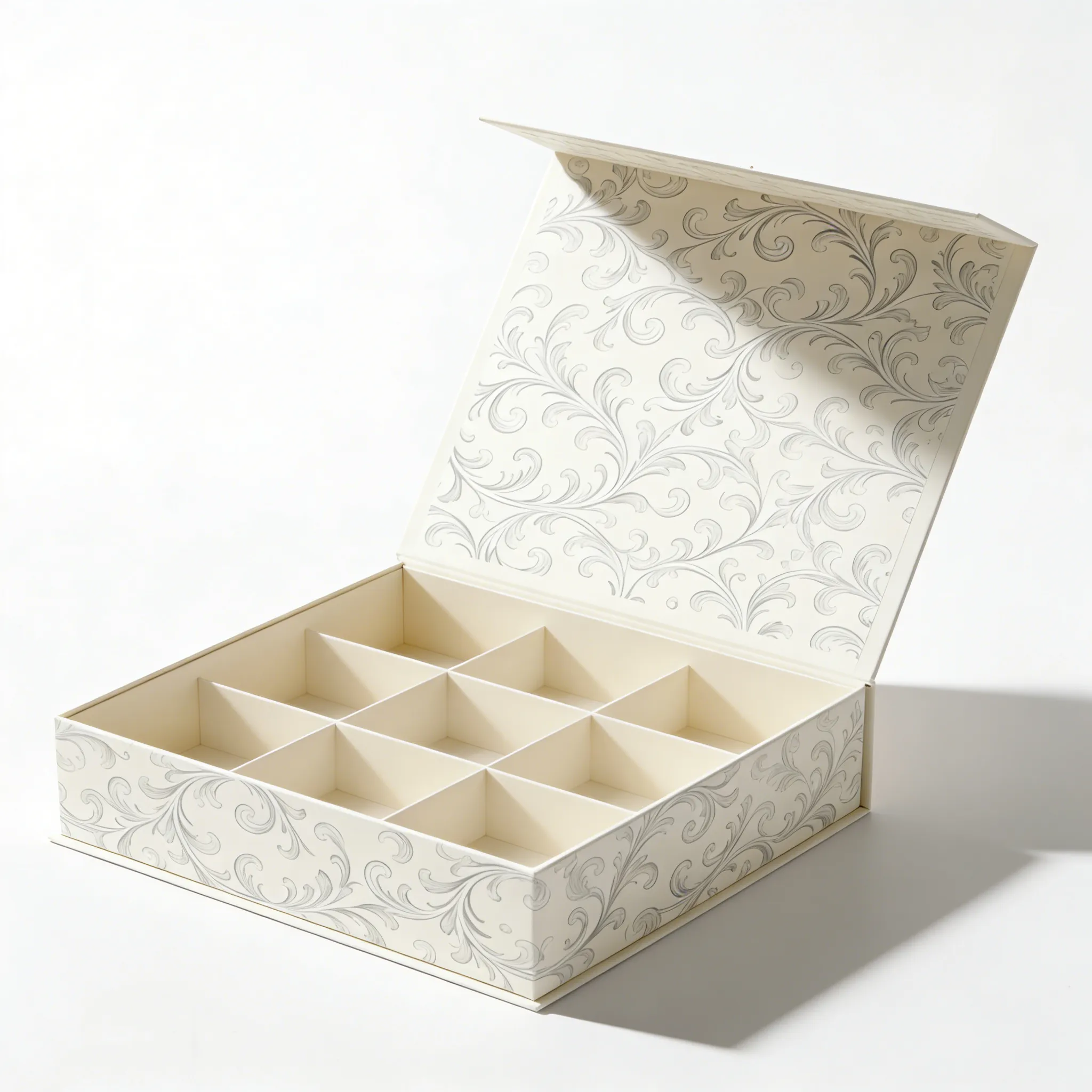

What is a Rigid Box?

Rigid box (set up box) made from thick paperboard, usually 800 gsm-2000 gsm, and covered with printed paper or decorative paper. It is provided pre-assembled and not collapsible.

Key Characteristics of a Rigid Box

- Sturdy, durable, and highly impact‑resistant

- Premium, gift‑worthy appearance

- Ideal for luxury and high‑value branding

- Supports complex structures (drawer box, magnetic lid, lift‑off lid, shoulder box, etc.)

- Higher material, labor, and assembly costs

Typical Applications

- Luxury cosmetics and skincare

- High‑end electronics

- Bijoux et montres

- Premium food and treats

- Gift sets and promotional kits

What Is a Folding Box?

A Boîte pliante (also known as a folding carton) is produced from thinner paperboard, usually 250gsm–600gsm. It is printed, die‑cut, glued, and shipped flat, then folded into shape during packing.

Key Characteristics of a Folding Box

- Lightweight and cost‑effective

- Ships flat, saving storage and freight costs

- Highly efficient for large‑volume production

- Flexible in size, printing, and structural design

- Less protective than a rigid box

Typical Applications

- Beauty and personal care products

- Food and snack packaging

- Household and daily‑use products

- Retail packaging for lightweight items

Rigid Box vs. Folding Box: Key Differences

Structure & Durability

- Rigid Box: Superior protection due to thick board and solid structure

- Folding Box: Suitable for lightweight products, limited impact resistance

Appearance & Branding

- Rigid Box: Naturally conveys a premium, luxury, and gift‑ready feel

- Folding Box: Excellent printing quality but less high‑end by default

Logistics & Storage

- Rigid Box: Cannot be flattened; requires more warehouse and shipping space

- Folding Box: Ships flat, significantly reducing storage and freight costs

Cost

- Rigid Box: Higher cost due to heavy materials and manual assembly

- Folding Box: More economical for mid‑range or budget products

Common Challenges When Choosing Between Rigid Box and Folding Box (With Solutions)

Challenge 1: Balancing Protection and Cost

Rigid boxes provide strong protection but increase packaging cost, while folding boxes are budget‑friendly but less protective.

Solutions pratiques :

- Use reinforced folding boxes with double‑layer structures or corrugated inserts

- Add paper trays or molded pulp inserts for stability

- Combine formats: folding outer box + rigid inner tray

- Standardize box sizes to reduce tooling and production costs

Challenge 2: Keeping Packaging Aligned With Brand Positioning

Some premium brands worry folding boxes feel “too basic,” while rigid boxes may feel excessive for everyday products.

Solutions pratiques :

- Upgrade folding boxes with foil stamping, spot UV, embossing, or matte/gloss lamination

- Use custom die‑cut windows or unique structures to enhance brand identity

- Keep rigid box designs minimal—luxury doesn’t need to be flashy

Challenge 3: Sustainability Concerns

Modern consumers and retailers increasingly demand recyclable and eco‑friendly packaging.

Solutions pratiques :

- Avoid plastic films or switch to recyclable laminations

- Replace EVA foam with paper, molded pulp, or corrugated inserts

- Print recycling instructions directly on the packaging

Challenge 4: Storage, Shipping & Inventory Pressure

Rigid boxes take up more space and increase logistics costs.

Solutions pratiques :

- Choose collapsible rigid boxes to reduce storage volume

- Use folding boxes for replenishment or secondary packaging

- Optimize packaging dimensions for pallet efficiency

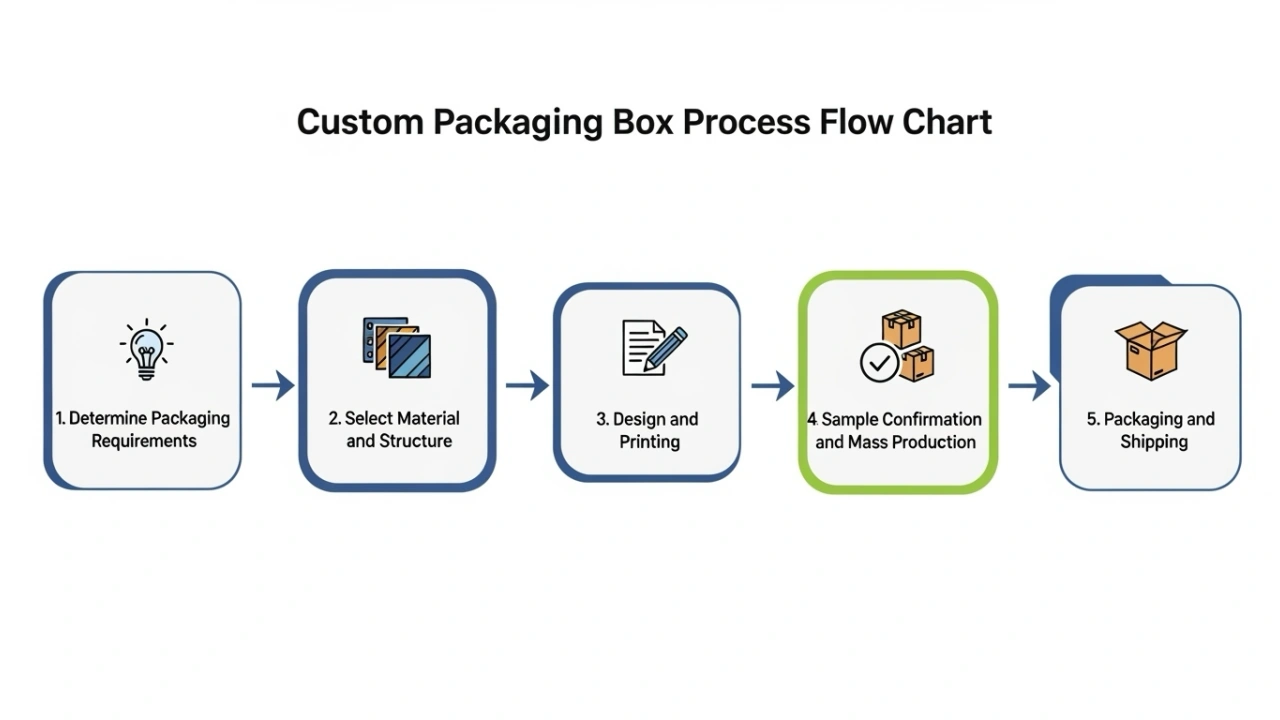

About Yisheng – Your Rigid Box & Folding Box Manufacturer

Yisheng est un professionnel fabricant d'emballages en papier spécialisée dans custom wholesale Rigid Box and Folding Box solutions.

Why Choose Yisheng?

Matériaux de qualité

Stable, sustainable, eco-friendly paper products are used in production to ensure that we protect our customers’ items consistently and provide an enjoyable unboxing experience.

Manufacturing Equipment

We have the state-of-the-art equipment needed to manufacture everything from cutting through to finishing rigid box and folding box products, ensuring stable production quality when we produce large volumes of product.

Customized Packaging

Our packaging is developed specifically to fit your brand and product needs, whether it’s using different box designs, printing styles, coatings, inserts, or closures.

Sustainable Packaging

All the materials we use to package our products can be recycled, composted, or produced from sustainable resources. By using these materials, we are reducing the overall environmental footprint of the products we package.

Customer Service Commitment

We offer our customers a completely transparent service experience based on clear pricing, straightforward communication and an easy-to-understand design process so that all aspects of your business with us will be simple for you from start to finish.

Conclusion

Rigid boxes and folding boxes, as part of modern packaging, are indispensable. Two types of the modern packaging industry, both rigid boxes and folding boxes, are critical to the standard, durable types of packaging in the present day. Superior protection is one of the key features of the rigid box, alongside the ability to deliver a premium presentation, whilst the folding carton is best known for its cost-effectiveness and flexibility in logistics.

For B2B buyers, what constitutes the best option depends on product value, brand positioning, sustainability goals, and supply-chain needs.

With years of production experience and flexible customization services, Yisheng supports brands in designing and producing packaging with functionality, cost-effectiveness, and visual impact – Rigid Boxes, Folding Boxes, or hybrid solutions.