When it comes to gift packaging, design often gets all the attention. But how to choose the gift box material choice? That’s the silent dealbreaker.

في ييشنغ, we’ve seen it all—from beautifully designed boxes that collapse during shipping, to luxurious appearances that fail under real-world use. Whether you’re a small business preparing for holiday sales or a corporate brand launching a premium product, the material you choose for your gift box can make or break your customer’s first impression.

This guide will walk you through:

- The most common gift box materials and their pros/cons

- How different usage scenarios call for different materials

- Common mistakes buyers make

- Practical advice on how to choose the right material

- Expert tips from a packaging manufacturer’s perspective

Why Gift Box Material Matters More Than You Think

Gift boxes aren’t just containers—they are part of your brand experience. The right gift box material:

- Enhances perceived product value

- Reinforces brand positioning

- Provides necessary strength and protection

- Supports premium finishes (like foil stamping or embossing)

- Meets environmental and functional needs (such as recyclability or water resistance)

For example, a rigid greyboard box lined with velvet communicates luxury and care. A kraft mailer with simple print tells a story of sustainability and honesty. But mismatch them? You risk sending the wrong message—or worse, delivering a broken product.

Common Gift Box Materials: Pros and Cons

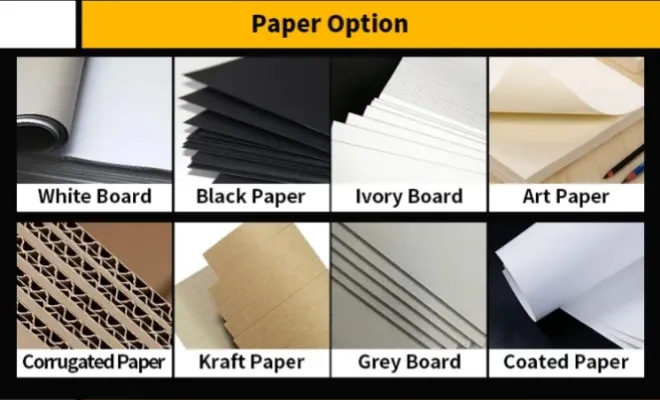

Here’s a breakdown of popular gift box materials:

Rigid (Greyboard) Paperboard

- المزايا: Dense, high-quality texture, ideal for luxury packaging and specialty finishes

- القيود: Heavy, more costly, not foldable

Corrugated Paperboard

- المزايا: Strong but lightweight, ideal for shipping and cushioning

- القيود: Not as refined look unless used with coated paper

Art Paper / Coated Paper

- المزايا: Smooth, high-quality print, ideal for surface treatments

- القيود: Requires lamination or backing to be structurally stable

ورق كرافت

- Benefits: Eco-friendly, recyclable, rough texture

- Limitations: Less suitable for bright colors or humid conditions unless laminated

Specialty Paper (Pearlescent, Textured, Embossed, Metallic)

- الإيجابيات: Tactile and beautiful, ideal for seasons or limited runs

- السلبيات: Higher cost, less accessible in small sheets

Match the Material to the Usage Scenario

1.Luxury Retail Packaging

Products: Jewelry, cosmetics, watches

Best choice:

- Rigid greyboard with art/specialty wrap

- Velvet lining, magnetic closure

- Foil stamping and embossing

Why: Customers expect elegance, structure, and premium finishes.

2.E-commerce Shipping

Products: Online orders, subscription boxes

Best choice:

- Corrugated mailers with a coated outer layer

- Internal dividers or inserts

- Simple foldable structures

Why: Strength and efficiency matter more than luxury, durability, with brand visibility is key.

3.Event or Promotional Gifting

Products: Corporate gifts, weddings, product launches

Best choice:

- Lightweight rigid board or foldable kraft

- Satin/foam inserts, coated wraps

Why: Boxes must look good without breaking the budget, be easy to ship and assemble.

4.Food and Edible Packaging

Products: Baked goods, teas, gift sets

Best choice:

- Food-safe kraft or laminated paperboard

- Greaseproof liners, PET window cut-outs

Why: Must meet hygiene standards and resist heat, grease, or humidity.

Common Mistakes Buyers Make When Choosing Materials

Even experienced buyers fall into traps when selecting gift box materials. Here are the most frequent missteps:

- Misunderstanding industry terms (“art paper” vs. “ivory board”)

- Focusing on cost instead of performance

- Ignoring environmental factors like humidity or stacking needs

- Choosing looks over function

- Skipping sampling or prototyping

These can lead to production errors, returns, or negative customer experiences.

How to Choose the Right Gift Box Material: Practical Tips from Yisheng

- Define the Purpose

Is this for gifting, transport, display, or storage? The function determines the structure and strength needed. - Consider Real-World Conditions

Will the box face humidity? Long transit? Fragile contents? These affect material choice. - Request Samples

Always ask for physical samples. Yisheng offers material swatches and prototypes for your review. - Involve Your Packaging Partner Early

Don’t finalize the design alone—consult your manufacturer in the planning phase to avoid rework. - Combine Materials for Performance + Aesthetics

Need a luxury look and durable core? Try rigid outer with corrugated inserts. - Check Compatibility with Surface Finishes

Some papers handle foil, embossing, or UV better than others. Test before mass production. - Think Green

Ask about FSC-certified paper, recycled board, or compostable coatings if sustainability is important to your brand. - Use Clear Visual Briefs

3D mockups, sketches, or photos help manufacturers better understand your expectations.

Why Yisheng?

ييشنغ محترف شركة تصنيع العبوات الورقية, specializing in:

- Custom rigid boxes, folding cartons, paper bags

- Premium finishes like foil stamping, embossing, UV

- Food-safe, eco-friendly, and shipping-friendly materials

- Structural design consultation + pre-production sampling

Whether you’re launching a product, preparing for a gifting season, or scaling your e-commerce business, we help you make material choices that work aesthetically, functionally, and economically.

للتواصل مع ييشنغ today to get expert packaging advice and start creating boxes that wow.