A modern paper package box does so much more than hold a product; it builds your brand story. Whether you are a retailer, a wholesaler, or a brand owner placing orders for customized boxes in bulk, knowing how a paper package box is made allows you to make far better decisions in terms of quality, cost, and sustainability.

ييشنغ specializes in the designing and manufacturing of all kinds of customized paper boxes for different industries. The following guide covers everything from the design and full production process to delivery and points out some of the common challenges and how we help brands meet professional, reliable, and eco-friendly results.

What is A Paper Package Box?

A paper package box is a form of packaging made from paperboard, corrugated board, kraft, or rigid stock. Its two major functions are simple but vital: protection of the product and improved presentation.

Compared to plastic or metal packaging, paper package boxes combine the advantages of structural strength with excellent printability and design flexibility, making them ideal for brand packaging.

الأنواع الشائعة من الصناديق الورقية

- Folding cartons: Delivered flat and easy to assemble; great for lightweight retail products.

- Corrugated boxes: These are fluted for strength and are utilized for shipping, heavier goods.

- Rigid boxes: These are high-end, non-collapsible boxes used in premium packaging.

- Kraft boxes: These are natural brown boxes that are best for eco-friendly or sustainable brands.

- Gift/retail boxes: can be fully customized for printing, foiling, magnetic closures, ribbons, and inserts.

From cosmetics and electronics to food, beverages, and gifts, paper boxes are used in every industry. Yet, the making of a quality paper package box requires more than just the printing logo; it requires precision in design, materials, and craftsmanship.

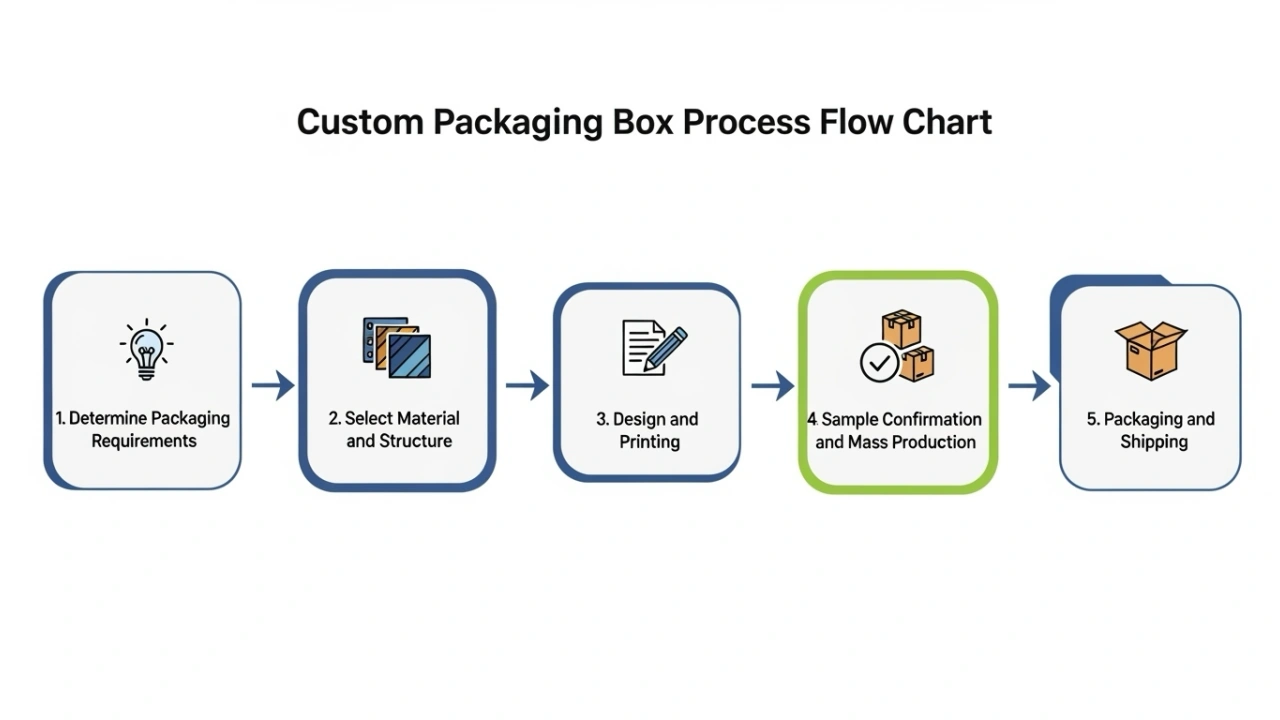

Paper Box Manufacturing Process

Step 1: Design & Specification

It starts with planning and design:

- Product fit: Measure the size, shape, and weight of your product.

- Dieline creation: The box structure is designed by the engineers, together with the folds and glue tabs.

- Graphic Design: Brand color, typography, and artwork are added with defined printing methods.

- Material selection: manufacturing with the right board type, either paperboard, corrugated, kraft, or other types, considering durability and sustainability.

- Prototyping: A prototype or sample is made to test fit, texture, and print accuracy before going into mass production.

Step 2: Pre-Production & Tooling

After approval, production setup begins:

- Steel dies and print plates are made.

- Digital or offset printing setups are calibrated.

- Clients approve the final printed sample.

- Production is scheduled based on order size and delivery timelines.

Step 3: Production & Finishing

- الطباعة: Artwork is printed on the selected material.

- Cutting & creasing: Boards are cut and scored with precision dies.

- Folding & gluing: Sheets are assembled into box form; extras like ribbons or windows can be added.

- Insert assembly: Inserts or dividers are fitted where required.

- Quality checks: Every batch is inspected for print accuracy, structural stability, and consistency.

- Packing & shipping: Boxes are flat-packed or pre-assembled, palletized, and shipped.

Step 4: Post-Production & Usage

- Storage: Keep boxes in a dry environment to avoid warping.

- Unboxing experience: Retail brands often test how customers open the box to ensure a premium experience.

- End-of-life: ييشنغ helps brands choose recyclable and biodegradable materials for sustainability goals.

Common Challenges in Paper Box Manufacturing

Design Mismatch

Sometimes the final product differs from the approved design due to:

- Warping after printing

- Color variations

- Folding or glue misalignment

- Incorrect insert fitting

الحلول:

- Request prototypes using actual production materials.

- Use calibrated color systems.

- Approve first production samples before mass production.

Material and Finish Selection

Choosing the right board thickness, coating, or insert type can be confusing.

الحلول:

- Create a comparison chart of materials vs. cost vs. protection.

- Get cost breakdowns for each finish type.

- Consult your manufacturer early for professional recommendations.

- Use modular box structures to balance customization and efficiency.

- Always consider sustainability and recyclability when selecting coatings or laminations.

Other Common Issues

- Tight production deadlines

- MOQ restrictions

- Color inconsistency

- Shipping damage

- Waste management

Best practices:

Plan buffer time, use certified suppliers, control storage conditions, and choose a paper package box manufacturer that manages waste responsibly.

Best Practices for High-Quality Paper Package Box Production

- Collaborate early: Align design, engineering, and sourcing teams from the start.

- Use eco-friendly materials: Choose recyclable boards and water-based inks.

- Check proofs carefully: Approve print proofs before full runs.

- Establish clear tolerances for fold and glue strength variabilities.

- Monitor production by randomly inspecting boxes during manufacturing.

- Design to cost: Use standard dielines, flat-pack designs wherever possible.

- Optimize for logistics: Choose board strength suitable for stacking and shipping.

- Add recycling guidance: Include icons or labels to encourage proper disposal.

How Yisheng Ensures Reliable Paper Package Box Manufacturing

Choosing a professional paper package box partner like Yisheng helps you avoid costly errors and delays. Here’s how we support your business:

- Prototyping & sampling: We provide structural and printed samples before mass production.

- Flexible customization: From magnetic closures to foil stamping, we customize every detail.

- Scalable production: Advanced machinery that is effective for both small and bulk orders.

- Sustainability commitment: We prioritize recyclable, eco-friendly materials.

- Transparent Communication: You will get clear quotes, updates, and full visibility on every order.

- Long-term partnership: We store your dielines and print files for consistent quality in reorders.

With ييشنغ, you get not only a box manufacturer but a packaging partner that makes sure your brand’s image, quality, and sustainability objectives are met every time.

الخاتمة

Making a paper package box is a process that involves detailed engineering combined with an artistic concept. Each step, from material selection to finishing, has its influence on the final quality and cost. The most common problems arise with inconsistencies in design or poorly chosen materials, but these are easily avoided with the right partner.

في ييشنغ, the fusion of technical expertise and sustainability with meticulous attention to detail goes into packaging to protect your products while elevating your brand. From bespoke gift boxes to food packaging and retail cartons, we will help you design and manufacture boxes that tell your story beautifully, efficiently, and responsibly.