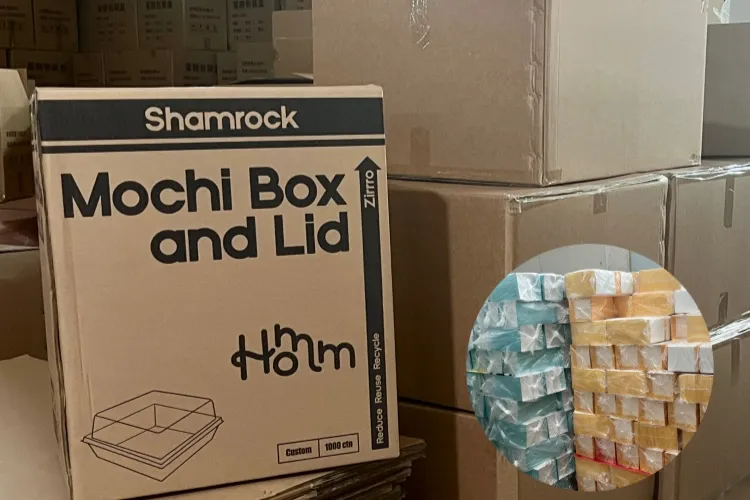

Packaging Box Manufacturing Capability for Custom & Wholesale Supply

Production Capability

As a professional packaging box manufacturer, our packaging box manufacturing capability covers a strong production capacity and flexible customization to mass-produce customized packaging solutions to meet orders with different needs. Multiple production lines and advanced equipment ensure an efficient and precise production process to make your packaging stand out in the market.

- 8000 Square Meters of Floor Space

- 10+ Production Lines

- About 10-12 Machines Per Production Line

- Annual Production Capacity of 20 Million

- Customization Flexibility

Well-established Industry Chain

As a well-established packaging box factory, Yisheng’s packaging box manufacturing capability undertakes every step in the industry chain from raw material procurement to innovative design, full production, and final delivery. Its full-process supply chain enables guaranteed, high-quality, and cost-effective output.

- Professional Design and Development

- Multiple Styles of Packaging Boxes

- Complete Production Equipment

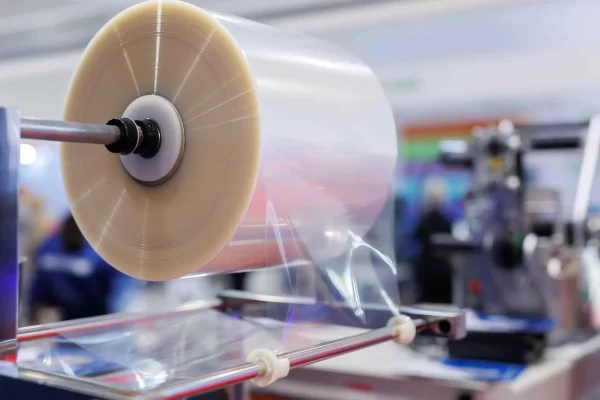

- PET, PVC, Various Paper Material

- Strict Quality Inspection

- After-sales Service

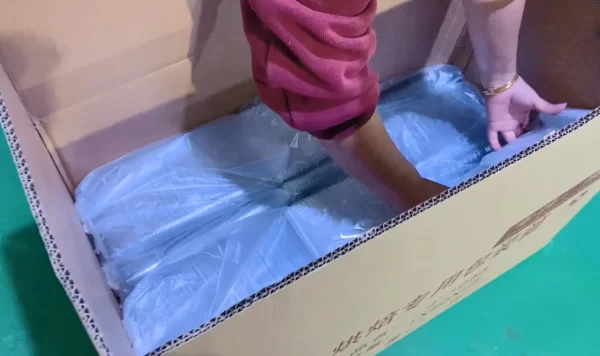

In-Stock Supply Capability

Yisheng is also a packaging box factory with abundant stock to respond quickly to urgent and short-term orders. Our flexible stock capability helps businesses adapt to market fluctuations and secure rapid business growth.

- Fast Shipping Within 3-5 Days

- 200+ Stock Models Available

- 4000+ m2 Warehouse In Stock

- Flexible Ordering

Your Trusted Partner in Packaging Box Manufacturing Capability

Production Process of Paper Packaging Box

Raw Material Preparation

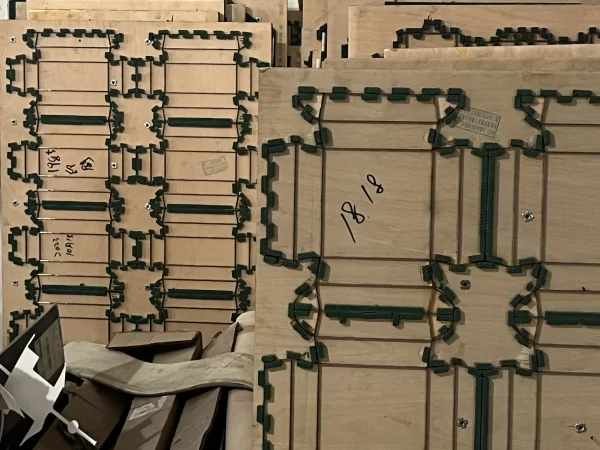

Design Plate Making

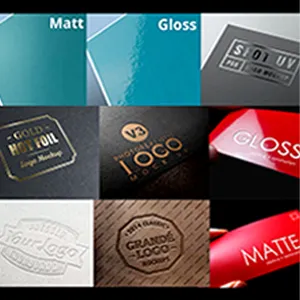

Printing

Surface Finishing

Die-cutting

Folding Molding

Quality Inspection

Storage Packing

Production Process of Plastic Packaging Box

Preparation of Plastic Sheet Materials

Mould design

Heat and Soften

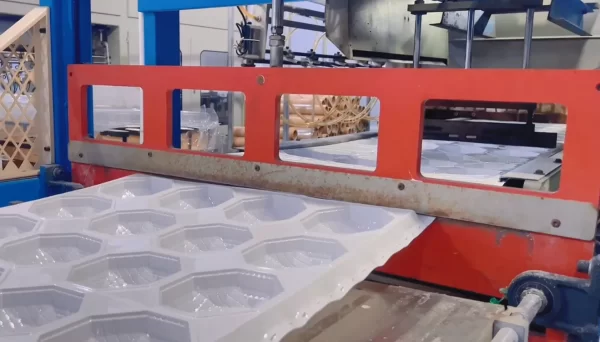

Blister moulding

Cooling and Curing

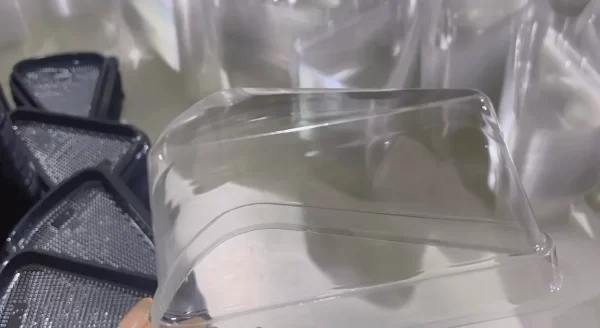

Demolding and Trimming

Quality Check